Aluminum Parts

CNC Machining Aluminum Parts Service

HRC Metal offers CNC machining services for aluminum parts, catering to a wide range of production needs from one-off prototypes to mass production runs exceeding 100,000 units, while delivering custom CNC machined aluminum parts that high quality with low prices and ensuring rapid turnaround times, with samples available as quickly as in just a few days.

Aluminum is one of the most widely used materials in the manufacturing world. Its lightweight, high strength-to-weight ratio, corrosion resistance, and excellent machinability make it ideal for various applications — from aerospace to consumer electronics. In modern CNC machining and fabrication, custom aluminum parts play a crucial role in delivering high-performance, durable, and aesthetically appealing products.

We’ll take a detailed look at aluminum parts—what they are, how they are machined, what materials are available, the surface treatments used to enhance performance and appearance, and their applications across various industries.

What are Aluminum Parts?

Aluminum parts refer to components or products made primarily from aluminum or its alloys, which are shaped, cut, formed, or cast using various manufacturing techniques. These parts can range from precision machined aerospace components to decorative parts in consumer electronics or sturdy frames in automotive construction.

Key characteristics of aluminum parts include:

Lightweight: About one-third the weight of steel.

Strong and durable: Especially when alloyed or treated.

Corrosion-resistant: Naturally forms an oxide layer.

Highly conductive: Excellent thermal and electrical conductivity.

Easily machinable: Ideal for CNC operations and fabrication.

Recyclable: Environmentally friendly and sustainable.

Aluminum parts can be customized with various surface finishes and treatments to suit the demands of specific environments and aesthetic preferences.

What are the Common Aluminum Processing Methods?

Aluminum can be processed in several ways depending on the desired properties, precision, production volume, and cost requirements. Below are three of the most common aluminum processing methods.

CNC Machining Aluminum

Sheet Metal Aluminum

Die Casting Aluminum

CNC Machining Aluminum

CNC machining is one of the most precise and versatile aluminum processing techniques. It involves removing material from a solid block (aluminum billet) using computer-controlled cutting tools.

Advantages:

High dimensional accuracy and repeatability.

Ideal for complex geometries and tight tolerances.

Suitable for prototypes, small batches, and mass production.

Compatible with a variety of aluminum grades like 6061, 7075, and 2024.

Common CNC processes for aluminum include:

Milling

Turning

Drilling

Tapping

Applications: Aerospace brackets, electronic enclosures, medical devices, automotive components.

Recommended aluminum grades for CNC machining:

| Grade | Properties | Applications |

|---|---|---|

| 6061 | Versatile, corrosion-resistant, good strength | General-purpose parts, aerospace |

| 7075 | High strength, less corrosion resistance | Structural, aerospace, military |

| 2024 | High fatigue resistance, moderate strength | Aerospace frames, structural components |

5-Axis CNC Machining Aluminum

If you want to get a machined aluminum part with high accuracy and complex geometries, 5-axis CNC machining may well fulfill your demands. The workpiece can be processed in multiple directions along with cutting in five angles of the axes simultaneously. Our advanced 5-axis CNC machines make it possible to complete all styles of aluminum milling tasks that require machined parts with extreme precision and complex shapes.

Efficiency

One single setup helps to save setup time, fasten the lead time, and increase productivity.

Intricate geometry

5-axis CNC machines with versatile configurations allow for the complex geometry of aluminum parts.

Higher accuracy & tolerance

Workpieces can be machined in a single run, thus quality is improved while error is reduced.

Higher spindle speeds and feed rates

The load on the cutting tool can be reduced by the use of more rigid and shorter tools.

Sheet Metal Aluminum

Sheet metal aluminum processing involves cutting, bending, stamping, or forming thin aluminum sheets into specific shapes or enclosures.

Advantages:

Cost-effective for large volumes.

Lightweight and flexible.

Quick production cycles.

Compatible with welding and joining techniques.

Common processes:

Laser cutting

Bending (CNC press brake)

Stamping and punching

Deep drawing

Applications: Enclosures, chassis, brackets, panels for electronics, HVAC, and automotive industries.

Die Casting Aluminum

Die casting is a process where molten aluminum is injected into steel molds under high pressure. This method is ideal for producing high-volume parts with consistent quality and complex shapes.

Advantages:

High production efficiency.

Excellent dimensional stability.

Minimal machining required post-casting.

Good surface finish and detail.

Applications: Automotive engine blocks, electronic housings, hardware fittings.

Common aluminum die casting alloys:

| Alloy | Features | Notes |

|---|---|---|

| A380 | High fluidity, good strength, corrosion resistance | Most commonly used in die casting |

| ADC12 | Japanese equivalent of A383, better pressure tightness | Popular for electronics |

What are the Materials of Aluminum?

Aluminum materials used in CNC and fabrication are typically alloyed to enhance their mechanical, thermal, and chemical properties. These alloys fall into two main categories.

Wrought Aluminum Alloys (for CNC, Sheet Metal)

These alloys are mechanically worked by rolling, extrusion, or forging.

| Alloy Series | Properties | Common Grades |

|---|---|---|

| 1xxx | Pure aluminum (99%+), excellent corrosion resistance, soft | 1050, 1060 |

| 2xxx | Copper alloyed, high strength, low corrosion resistance | 2024 |

| 3xxx | Manganese alloyed, good formability | 3003 |

| 5xxx | Magnesium alloyed, strong, corrosion-resistant, weldable | 5052, 5083 |

| 6xxx | Magnesium and silicon alloyed, great all-around properties | 6061, 6082 |

| 7xxx | Zinc alloyed, extremely high strength | 7075 |

Cast Aluminum Alloys (for die casting)

These alloys are specifically formulated to improve fluidity and casting performance.

| Alloy | Description |

|---|---|

| A356 | Excellent casting and machining properties, used in aerospace and automotive |

| A380 | General-purpose die casting alloy |

| ADC12 | High pressure die casting, ideal for thin-walled parts |

Choosing the right material depends on:

Strength requirements

Corrosion resistance

Machinability

Weldability

Cost constraints

Application-specific needs

Aluminum Surface Treatment

Surface treatment is essential to improve the durability, corrosion resistance, and appearance of aluminum parts. It also allows the addition of colors and finishes tailored to brand and function.

Anodizing

Anodizing is an electrochemical process that thickens the natural oxide layer on the surface of aluminum.

Benefits:

Corrosion and wear resistance

Electrically insulating

Available in various colors

Suitable for 6061, 5052, 7075, etc.

Types:

Type I (Chromic): Thin coating, corrosion protection

Type II (Sulfuric): Decorative, colorable, moderate thickness

Type III (Hardcoat): Thick, hard, wear-resistant

Applications: Electronics housings, automotive parts, consumer devices

Sandblasting

Sandblasting is a surface treatment process that uses high-speed abrasive particles (such as aluminum oxide or glass beads) to impact the aluminum surface. It removes oxidation, burrs, and contaminants while creating a uniform matte texture. This not only improves the aluminum’s appearance but also enhances adhesion for subsequent treatments like anodizing or coating.

Advantages of Sandblasting:

Effectively removes oxidation, stains, and machining residues

Produces a smooth, even matte finish

Increases surface roughness for better coating adhesion

Can be used alone as a decorative finish or as pretreatment for anodizing/painting

Environmentally friendly, with no chemical residue

Powder Coat

Powder coating is a dry finishing process where powder resin is electrostatically applied and cured under heat.

Benefits:

Thick, uniform coating

Durable and impact-resistant

Environmentally friendly (no solvents)

Wide color and texture options

Applications: Outdoor furniture, bicycle frames, electrical enclosures

24-Hour Quotes, Faster Than Industry Standards!

✔ ±0.01mm precision – 5-axis CNC machining guaranteed

✔ ISO 9001 certified – Full process & material traceability

✔ Aerospace-grade alloys (6061/7075) – 12+ finishes available

✔ 72-hour prototypes – Bulk discounts & fast delivery

Aluminum Applications in Various Industries

With the rapid development of technology and personalized needs, aluminum has become one of the most popular metal materials in the consumer electronics field and its derivatives due to its light weight, beautiful appearance, durability, easy processing, and anodizing coloring.

Snus Can

The snus can is a compact aluminum container often used for storing snus, chewing gum, or small items.

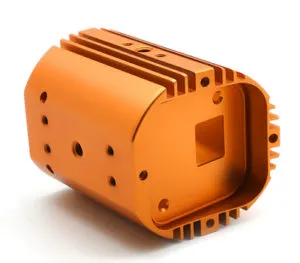

Heat Sink

Aluminum’s excellent thermal conductivity and formability make it the ideal material for electronics heatsinks.

Shift Knob

Aluminum gear shifters are functional and aesthetic elements in vehicles and smart mobility devices.

Speaker Parts

Aluminum is used in speaker components such as enclosures, driver frames, and decorative panels.

Snus Can

Aluminum snus cans are premium containers used to store snus, mints, or other small items. These are typically CNC-machined for precision and then anodized for enhanced durability and appearance. Brands often customize them with laser engraving or sandblasting for a stylish, unique look.

Key Features:

Surface finish: Anodizing, sandblasting, laser engraving

Processing method: High-precision CNC turning and milling

Product benefits: Lightweight, corrosion-resistant, tactile metallic feel

Heat Sink

Aluminum heatsinks are vital for thermal management in devices like laptops, LED lights, power amplifiers, and chargers. Thanks to aluminum’s excellent thermal conductivity, these components are made using extrusion, stamping, or CNC machining, enabling efficient heat dissipation and compact design.

Key Features:

Surface finish: Anodizing (anti-oxidation), coating (aesthetics)

Processing: Extrusion, CNC milling, stamping

Product benefits: Rapid heat transfer, lightweight structure, customizable forms

Shift Knob

As part of automotive consumer accessories, aluminum shift knobs are designed to enhance both appearance and tactile experience. CNC-turned and anodized, they offer a sleek, customizable finish, high rigidity, and wear resistance. Sandblasted surfaces provide a matte, premium feel, elevating the vehicle’s interior aesthetics.

Key Benefits:

Customizable colors and shapes for personalization

Strong and durable for long-term use

Lightweight and smooth to operate

Sandblasted + anodized for scratch resistance

Speaker Parts

Aluminum is used in speaker components such as enclosures, heat sinks, driver frames, and decorative panels. Its excellent acoustic neutrality, rigidity, and heat dissipation make it a preferred material for premium audio devices like wireless speakers, smart assistants, and soundbars.

Key Features:

Surface finish: Anodizing, electrophoretic coating, sandblasting/brushed

Processing: CNC machining, stamping, die casting

Product benefits: Acoustic stability, elegant look, heat resistance

Display of Our CNC Aluminum Parts

HRC Metal machined aluminum parts are used for automotive, defense, aerospace, transportation, construction, packaging, electronics, consumer goods, and more.

CNC Aluminum Machining FAQs

What is CNC aluminum machining?

CNC aluminum machining process involves machining a type of aluminum as the raw material to produce a wide type of desired products ranging from furniture to semiconductor chips. The high precision and exact geometry will be realized by a computer numerically controlled (CNC) milling tool.

Which type of aluminum is mostly used for CNC milling?

More than the general properties in which an all-purpose aluminum will suffice, aluminum alloy 6061 stands out for its high performance. So it’s qualified for CNC milling.

What are the benefits of CNC machining aluminum?

The CNC machining process can be improved and simplified by the use of aluminum. Compared to other metals like iron or steel, aluminum is easier to be chipped and shaped, allowing for a shorter manufacturing time.

- Good machinability

- Durability

- Corrosion resistance

- Electrical conductivity

- Recyclability

- Low cost

- Full versatility

- High strength-to-weight ratio

- Anodisation potential

How much does it cost for CNC machined aluminum parts?

The cost will extremely rely on the size, material grades of aluminum, and geometry of the part, as well as the type of fabrication machine required for your applications. Our intelligent quote system can make correct pricing quickly from the 3D CAD file, based on thousands of valuable data from previous CNC machining orders. What you need to do is just upload your CAD file online. The free quote will be sent to you within 24h.

We will Continue to Forge Ahead in CNC Aluminum Machining

Whether you require machined aluminum prototypes or custom aluminum parts for your automotive, aerospace applications or medical device component, we can easily help you. With our expertise in CNC aluminum machining and the ability to integrate external combined processes, we can ensure the best performance for your machining aluminum projects.