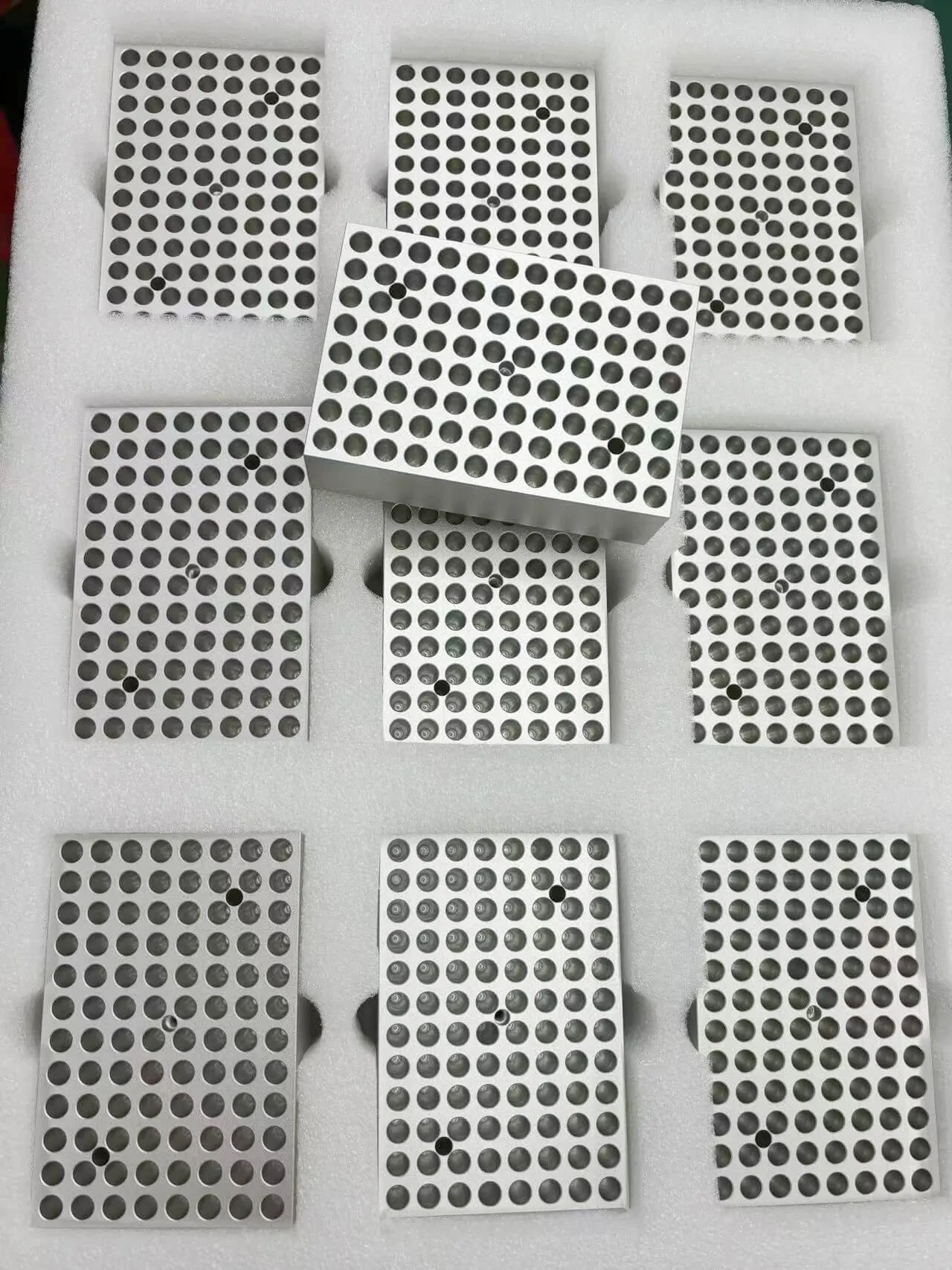

custom Medical parts

- Strict quality control

- High production efficiency

- No need to make special molds, saving time and cost

Advantages of CNC machining for the medical industry

1. Good repeatability

After the program is set, parts of the same specifications can be repeatedly produced to ensure the stable and consistent quality of mass-produced products, which is essential for large-scale production of medical parts.

2. Wide material adaptability

It is suitable for a variety of materials such as stainless steel, titanium alloy, medical-grade plastics, ceramics, etc., to ensure that the performance and biocompatibility of the material are not affected during the processing.

3. High production efficiency

The high degree of automation reduces the manual operation links and can achieve 24-hour uninterrupted production. It can provide high-quality parts in a short time to meet medical emergency needs.

4. Strict quality control

The automated processing process reduces the variables and errors introduced by human operation, and many CNC machines are equipped with online detection systems to monitor the processing quality in real-time to ensure that the products meet strict medical standards.