Introduction

In modern manufacturing, metal sandblasting is a very important and revolutionary surface – treatment technology. It’s an essential part of many industries, like aerospace, automotive, construction, and electronics. This technology has a long history and keeps changing. It has greatly affected the quality, performance, and look of metal products.

A Brief History of Metal Sandblasting

Metal sandblasting started in the late 19th century. At first, it was a simple process, mostly done by hand. Workers used basic tools to put abrasive materials on metal surfaces. But in the past hundred years or so, big technological changes have made it a very advanced and automated process. These changes have not only made sandblasting faster and more accurate but also made it used in more industries.

The Core Principle of Metal Sandblasting

How It Works

Metal sandblasting uses high – speed abrasive particles to hit the metal surface. Compressed air makes the abrasive particles move. It can make them go at speeds from dozens to hundreds of meters per second. When these fast – moving particles hit the metal surface, they do things like cut a little bit and change the shape of the surface. This process can clean off dirty things, change how the surface looks, and make the metal’s surface better.

Components of Sandblasting Equipment

Sandblasting equipment has several important parts. The compressed air system makes the high – pressure air needed to push the abrasive. The abrasive supply system stores and gives out the abrasive materials carefully. The spray gun is the tool that sends the air with abrasive to the metal surface. And there’s often a recovery system to collect the used abrasive and dust. This is important for saving money and protecting the environment.

Selection of Abrasive Media

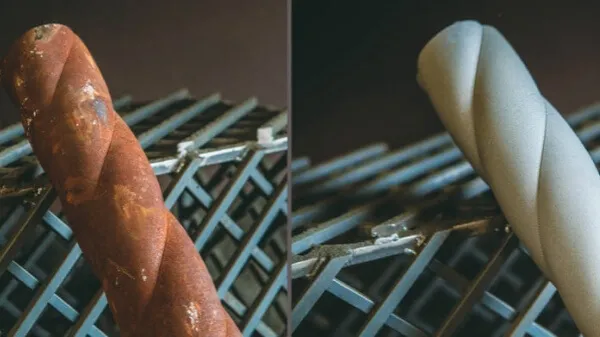

Choosing the right abrasive media is very important in metal sandblasting. Different media have different features that affect how sandblasting works. For example, steel sand is hard. It’s often used for tough surface cleaning and making the surface rough. Glass beads are soft. They’re better for getting a smooth surface, like when finishing some precision parts. Aluminum oxide is known for being very hard and stable. It’s a popular choice when we need to change the surface of materials to a high quality.

Industrial Applications of Metal Sandblasting

Surface Cleaning

One common use of metal sandblasting is surface cleaning. Metal surfaces often get dirty with things like oxide scale, rust, and oil stains over time. Sandblasting can clean these things off well. In the automotive industry, before painting or coating car bodies, sandblasting is used to clean the metal. This helps the paint or coating stick better. Compared to old chemical cleaning methods, sandblasting is better for the environment because it doesn’t leave harmful chemicals.

Surface Strengthening

Surface strengthening is another important use. By controlling the sandblasting settings well, we can make a layer of pressure on the metal surface. This layer can make the metal stronger against getting tired and corroding. In the aerospace industry, many important parts, like turbine blades and engine casings, are sandblasted to get stronger. This helps these parts stand up to the very strong forces and high temperatures during flight.

Surface Modification

Metal sandblasting is also used a lot for surface modification. It can control how rough the metal surface is. When we need a certain surface roughness for coatings to stick better or for other uses, sandblasting can help. In the electronics industry, when making printed circuit boards, sandblasting is used to make a good surface for putting on conductive materials and soldering.

The Role of Metal Sandblasting in Different Industries

Aerospace Industry

In the aerospace industry, metal sandblasting is very important. Aircraft parts need to be very good, with great mechanical properties and exact surface finishes. Sandblasting is used to clean, strengthen, and change the surfaces of parts like wings, fuselages, and engine parts. Using good sandblasting methods can make parts lighter while still keeping them strong. This is very important for saving fuel and making the plane fly better.

Automotive Industry

In the automotive industry, sandblasting is used at different times when making vehicles. It’s used to clean and get metal parts ready for painting, plating, or other finishing work. Sandblasting also makes parts last longer by making their surfaces stronger. For example, the chassis and suspension parts of cars are often sandblasted to make them better against wear and corrosion.

Construction Industry

In the construction industry, metal sandblasting is used for steel structures. Bridges, buildings, and other big construction projects use steel parts. Sandblasting is used to remove rust and get the steel surfaces ready for painting or coating. This protects the steel from getting more corroded and makes the structures last longer.

Development Trends of Metal Sandblasting Technology

AI and Automation

Making sandblasting equipment smart and automated is a big trend. With machine vision and artificial intelligence, modern sandblasting systems can know the shape and surface condition of workpieces by themselves. Then these systems can change the sandblasting settings right away. This makes the treatment quality always the same. For example, when making parts with strange shapes, smart sandblasting equipment can change to fit the different surface shapes and give even treatment.

Development of New Abrasive Media

People are also always working on new abrasive media. Nanoscale ceramic particles and biodegradable polymer particles are new materials. Nanoscale ceramic particles can cut better and get very fine surface finishes. This is important for making very precise things. Biodegradable polymer particles are better for the environment. They’re good for uses where we want to make less of an environmental impact.

Green and Environmentally Friendly Technologies

Because people are more worried about the environment, using green and friendly technologies in metal sandblasting is getting more important. Closed – loop sandblasting systems are being made to let out less dust and abrasive particles. Also, recycling and reusing abrasive materials is being encouraged. Some companies are trying water – based sandblasting methods. These make less dust and are better for the environment than old dry sandblasting.

Challenges and Solutions in Metal Sandblasting

Dust Emission and Environmental Impact

One big problem in metal sandblasting is dust. When the abrasive particles hit the metal surface fast, a lot of dust is made. This dust can be bad for the environment and people’s health. To fix this, new dust-collection systems are being made. These systems use filters and cyclones to catch the dust particles. This makes sure the air from the sandblasting process meets environmental rules.

Cost-effectiveness

The cost of sandblasting can be a problem, especially for big – scale production. The cost of abrasive materials, equipment upkeep, and energy use can add up. To make it cheaper, companies are focusing on recycling and reusing abrasive materials. New, more energy – saving sandblasting equipment is also being made to use less energy.

Conclusion

Metal sandblasting has changed a lot from being a simple hand – done process. It’s now a very important technology in modern manufacturing and is used in many industries. As sandblasting technology keeps getting better in terms of equipment automation, new abrasive media, and being friendly to the environment, it will have even more uses. When new materials and manufacturing processes come out, metal sandblasting will still be important for making metal products better. It helps the whole manufacturing industry move forward. It’s not just a surface-treatment technology but also a key thing for innovation and being competitive in the world’s manufacturing.