Speaker Parts

speaker components

From individual parts of a speaker (tweeters, woofers, crossovers) to full amplification speakers systems our DIY speaker kits – perfect for audiophiles and makers!

CNC Speaker Components Manufacturing

Crafted with CNC-machined aluminum and precision sheet metal fabrication, our parts of a speaker deliver unmatched durability and acoustic clarity. From rugged outdoor speakers with weather-resistant speaker cabinets to studio-grade amplifiers with milled control knobs, every component is optimized for premium sound. Build your ideal system with our bass speaker kits, featuring laser-cut enclosures and machine-finished drivers for deep, distortion-free lows.

speaker cabinet

Pro-grade sheet metal speaker cabinets: CNC-punched, laser-cut panels with seamless welds for superior acoustics.

LoudSpeaker

CNC-milled aluminum loudspeaker panels is ±0.1mm tolerance, anodized finish for acoustic precision.

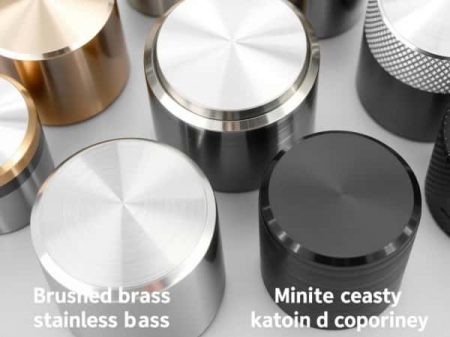

control knob

Precision CNC-turned aluminum knobs with anodized finish, non-slip grooves, perfect for audio controls.

outdoor speakers

CNC-machined aluminum outdoor speaker housings, anodized corrosion resistance, for harsh environments

speaker cabinet

Utilizing CNC precision stamping and laser cutting technology to accurately construct Car Speaker Cabinet structures; high-precision bending and seamless welding ensure airtight integrity and eliminate resonance. Features electrostatic spray coating for scratch-resistant durability, with optional Speaker Cabinet Carpet finishes. Customizable Speaker Cabinet Kits cater to DIY modifications, delivering professional acoustic performance in Speaker with Box systems.

Dual-application design for stage/vehicle (Speakers Box)

1.5mm cold-rolled steel or aluminum options

Pre-installed terminals and shock-absorbing feet

CNC Precision in Cabinet Construction

CNC machining has transformed how speaker cabinets are manufactured. Computer-guided cutting tools create perfectly dimensioned panels, precisely positioned driver cutouts, and acoustically optimized port tubes. This level of precision ensures:

- Exact driver alignment for optimal sound staging

- Perfectly sealed enclosures that prevent air leaks

- Consistent internal volumes for predictable bass response

- Precise port dimensions for tuned bass reflex systems

Sheet Metal Applications in Speaker Components

Sheet metal processing delivers exceptional results for various parts of a speaker:

- Reinforced steel or aluminum baffles that minimize vibration

- Precision-bent brackets for secure driver mounting

- Custom grille frames with perfect perforations

- Internal bracing that eliminates cabinet resonance

LoudSpeaker Panel

Custom Specifications for Loudspeaker Decorative Panels. Crafted with high-precision CNC machining technology, our loudspeaker decorative panels can be fully customized to meet specific design requirements. Manufactured from premium aluminum alloy using advanced CNC equipment, each panel guarantees flawless detailing. The surfaces are anodized for enhanced wear/corrosion resistance, with multiple color options available. We provide end-to-end design-to-production services for high-end audio systems.

±0.05mm Ultra-Tolerance – Ensures perfect alignment with speaker structures, eliminating assembly gaps

Mirror-Grade Finish – Ready for anodizing without secondary polishing

Intricate Pattern Reproduction – Accurately replicates complex custom designs

- Brush: Produces parallel/radial textures, hairline or snowflake patterns while retaining the substrate’s natural color, ideally showcasing the inherent beauty of aluminum or stainless steel.”

- Sandblasting: Creates micro-dimples that enhance anodic film adhesion, improving wear resistance by over 30%. The matte surface reduces fingerprint retention for easier cleaning.

Control Knob

The humble control knob represents a critical interface between user and audio system. CNC-machined knobs deliver both aesthetic appeal and precise control for amplification speakers and audio equipment.

Bass Control Knob Precision

A quality bass control knob provides tactile feedback and precise adjustment. CNC machining allows for:

- Perfectly balanced rotation with zero wobble

- Precise detents for repeatable settings

- Ergonomic designs that feel substantial

- Custom knurling patterns for improved grip

Materials That Make a Difference

The materials used in knobs controllers significantly impact both feel and durability:

- Aircraft-grade aluminum for lightweight precision

- Solid brass for substantial feel and classic appearance

- Stainless steel for maximum durability

- Carbon fiber composites for modern aesthetics

Outdoor Speaker Durability

Outdoor speakers face unique challenges from weather exposure, temperature fluctuations, and UV radiation. Precision sheet metal fabrication and CNC machining create enclosures that protect sensitive components while maintaining acoustic performance.

Weather-Resistant Enclosures

Outdoor bluetooth speakers rely on precision-manufactured enclosures to protect internal components:

- Marine-grade aluminum housings with watertight seals

- Precision-molded drainage channels that prevent water accumulation

- UV-resistant powder coating applied to exact specifications

- Corrosion-resistant hardware with perfect thread alignment

DIY Speaker Kits & Customization Options

The growing popularity of DIY speaker kits reflects audio enthusiasts’ desire for customization and value. These kits combine precision-manufactured components with the satisfaction of personal assembly.

Build Your Own System

Premium speaker parts ensure seamless DIY integration, allowing enthusiasts to create custom audio solutions with professional-grade performance. Each component is manufactured to exacting tolerances for perfect fit and optimal acoustic properties.

Benefits of CNC Precision in DIY Kits

DIY speaker kits benefit tremendously from precision manufacturing:

- Perfect component alignment without specialized tools

- Pre-cut cabinets that assemble with minimal woodworking skills

- Precisely matched drivers and crossover components

- Detailed assembly instructions with exact specifications

Customization Possibilities

The true value of DIY speaker building lies in customization options:

- Cabinet finish selections from exotic veneers to custom paint

- Driver upgrades for specialized audio characteristics

- Crossover modifications for personalized frequency response

- Custom port tuning for optimized bass performance

Start Your DIY Speaker Project Today

Browse our selection of complete DIY speaker kits and individual components to create your perfect audio system.

Behind the Scenes: Manufacturing Speaker Parts

Understanding the manufacturing processes behind quality speaker parts helps enthusiasts appreciate the engineering that goes into each component.

CNC Machining Process

Computer-guided cutting tools transform raw materials into precisely dimensioned components with tolerances measured in thousandths of an inch.

Sheet Metal Fabrication

Advanced bending, punching, and welding techniques create structural components that combine strength with precise acoustic properties.

Quality Control Testing

Each component undergoes rigorous testing to ensure dimensional accuracy, structural integrity, and acoustic performance.

Elevate Your Audio Experience with Precision-Crafted Components

The journey from raw materials to finished speaker parts involves sophisticated engineering and manufacturing processes that directly impact audio performance. Whether you’re building a complete DIY speaker kit, upgrading individual components, or designing outdoor audio systems, the precision of each part matters.

CNC machining and advanced sheet metal fabrication have revolutionized what’s possible in speaker design, allowing for tighter tolerances, innovative geometries, and superior acoustic properties. These manufacturing advances translate directly to better sound reproduction, greater durability, and enhanced user experience.

By investing in precision-crafted speaker parts, you’re not just building an audio system—you’re creating an experience that will deliver exceptional sound quality for years to come.

Ready to discuss your custom aluminum speaker Parts project?

Fill out the form below our team will feedback within 24 hours.